Alvis: inside the carmaker you've never heard of

Continuation models. A newfound phenomenon of the car industry and a prickly talking point for monied collectors. You may’ve noticed a load of them sprout out of factories in the last few years, normally for crazy prices; there’s been continuation Jaguar XKSS and lightweight E-Types, a Bentley Blower, Aston’s DB4 GT, Zagato and even James Bond’s DB5 complete with gadgets.

It doesn’t stop there: Range Rovers, Lister Knobblys and Shelby Daytona Coupes have all been dragged out of the grave and sold as new-old cars. But there’s one you might not have heard of. And a proper, bona fide continuation to boot: Alvis.

STORY Rowan Horncastle

PHOTOS Mark Riccioni

See, a continuation car is not a restoration or replica. They’re cars that have been taken out of the cryogenic freezer; built from scratch in accordance with the original standards and engineering plan, although some contain modern components.

Some OEMs continue the original VIN numbering right where it left off, some start again at zero. This irks some enthusiasts, especially as they’re being sold for millions of pounds. But Alvis does continuations with added authenticity.

Mainly because the people building the cars effectively went for a tea break in 1966 and didn’t come back until 2012. The parts and methods they’re using to build the car haven’t changed in that time. It’s just some have laid dormant for over 50 years old. But they’re also technically brand new. Get your head around that one.

But who the heck is Alvis? No, it’s not a ropey Elvis Presley cover band. It’s a car company. And if you’re young enough to remember Tesco’s “computers for schools” vouchers, we don’t blame you for not knowing who they are.

Why they’re not well-known is also quite surprising, as they were a manufacturing powerhouse, knocking out cars for the rich and famous as well as contributing to the war effort. But the company was also a breeding ground for engineering savants back in the days of black and white and World Wars.

Time for a history lesson. Alvis was founded by TG John in 1919. Even though he sounds like a Victorian YouTuber, TG John was actually a naval architect and marine engineer from South Wales. He later teamed up with engine designer Geoffrey de Freville in 1922 to build cars. But back then the way you bought and built cars was very different from today.

Instead of selecting a model and then lobbing on an ST, AMG or S-Line trim level like nowadays, when everyone was smoking pipes and riding penny farthings, you’d go to someone like Alvis for a chassis, then ask them to ship it to your desired coachbuilder to plonk a body on top.

Bentley and Rolls-Royce were Alvis’ main competitors. As a frame of reference, in the 1930s a house would cost £250. An Alvis could be up to £1500 – more than a Bugatti. Which is our kind of house-to-car ratio. They could also come with crazy parallel door hinges like this. Eat that suicide doors.

The coachwork dictated how each car would look, and the scope and range would change massively. You could get a four-door sports saloon from coachbuilders Charlesworth, a four-seater sports coupé or four-door tourer by Cross & Ellis, but some cars were supplied in chassis form and carried bodies by coachbuilders such as Vanden Plas.

Whereas Lancefield did all kind of bespoke and kooky design, complete with crazy hinges, tech and pull-out boots. But cars being expensive, new tech, the best way to market them was by proving their reliability. And there was only one way to do that: motorsport.

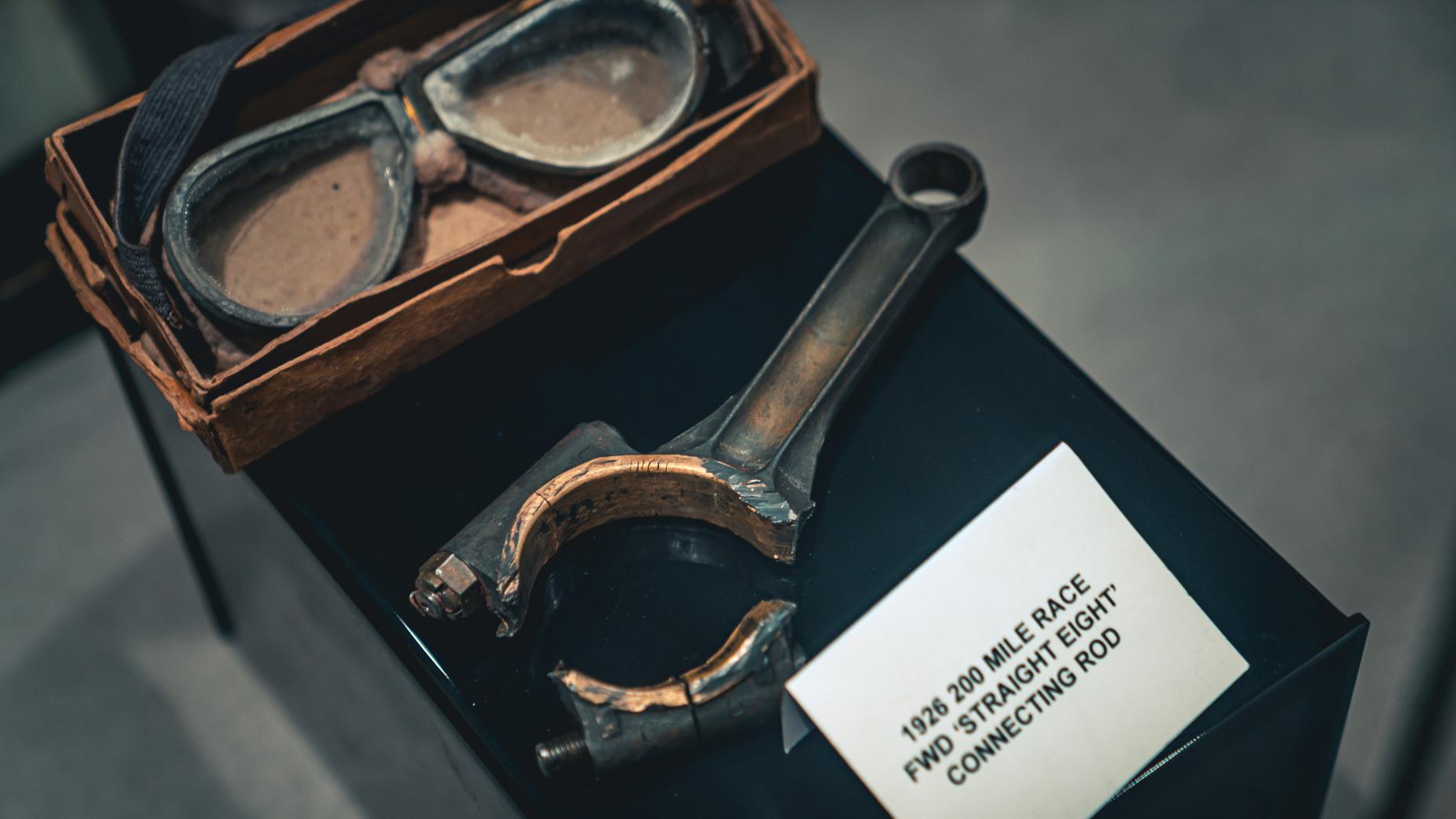

Alvis went into motorsport in 1923, enjoyed racing success at Le Mans in 1928 with 1.5-litre cars coming first and second in their class and sixth and ninth overall to beat Bentley in the Performance Index.

Oh, and they were front-wheel drive – beating the Nissan GT-R LM Nismo Le Mans racer’s innovative layout by nearly 90 years.

Technical innovation was abundant at Alvis. Furiously over-engineering components and using other industries as inspiration, Alvis lay claim to the world’s first front-wheel-drive production car, the world’s first all-synchromesh gearbox (designed at home by an intern in 10 weeks), the first use of independent front suspension and servo-assisted brakes.

They also made potty straight-eight, supercharged front-drive competition cars which were snapped up by boy racers at the time… and hated by insurers due to their backward differential then gearbox, then engine layout. In spirit then, these were the Honda Civic Type Rs of the day. And crashed just as readily.

Alvis’ were fast too, with one hitting 190km/h at Brooklands and the saloon being the first production four-door capable of the ton, then all other models being capable of triple figures – something that was unheard of at the time.

With clientele including Group Captain Sir Douglas Bader – the double-amputee flying ace of the Battle of Britain – and the Duke of Edinburgh, production continued into the 1960s with the factory at Holyhead Road covering 29 acres and employing over 20,000 employees.

But the cars had to stop when different variables came into play; the fact coachbuilders were no longer in business, the sharp rise of Japanese cars and Alvis’ military contracts being more profitable.

So in 1968 Alvis shut up shop, moving its passenger car interests to Kenilworth under the name ‘Red Triangle’, including all the quarter of a million spare parts, 50,000 technical drawings, and drawers of customer correspondence.

Having produced 22,000 cars, the role of Red Triangle was to service and maintain the 20 per cent of those still on the road. But then, in 1994, a man called Alan Stote came along.

Having always been interested in cars, as well as a collector of various things, plus an enthusiast about all things 20th Century history, he decided to buy the Alvis name plus all of the lost stock as it was all those things he loved combined in one project. It also helped he was an avid Alvis owner. And, having sold a manufacturing company, also had some pretty pennies in his bank account.

Now he had possession of all the original wax paper drawings from the Thirties, and Red Triangle were already making most parts of the car as spares – Alan thought ‘why not go the whole hog and build some new ones?’ Not, like an Eagle E-Type, an extra-thorough restoration/modification of an old car, but an actual new car, from the ground up.

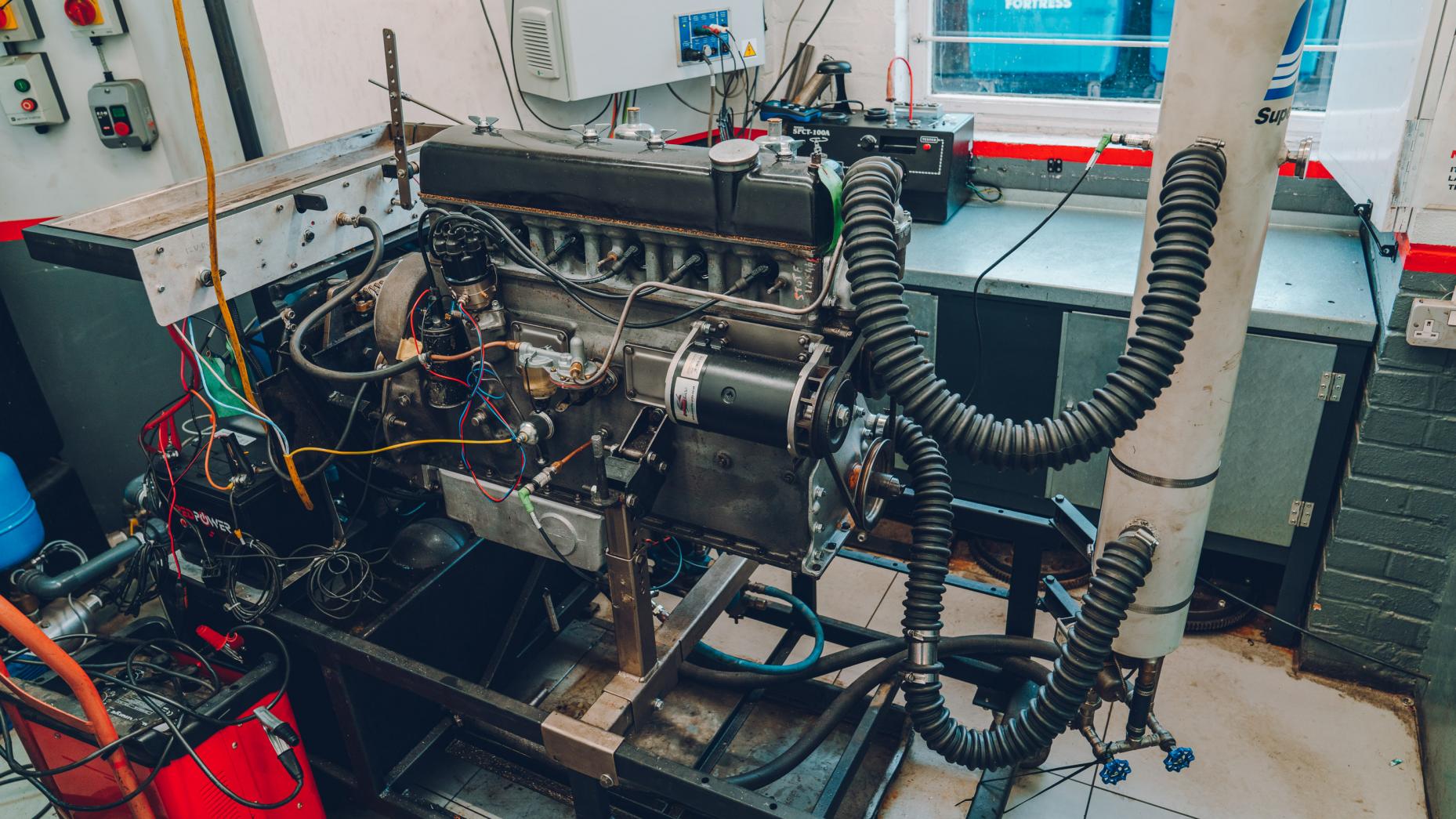

The first thing to do to make continuations happen was to make the cars 2020 friendly. Which meant those engines that had sat in boxes for nearly 50 years had to pass modern emission standards.

You’d think a post-war 3.0-litre and pre-war 4.3-litre cars would be filthy little things that’d fail miserably. Well, with the help of a former Technical Director from Lotus, they tweaked a few bits and got it to sail through.

And to keep VOSA happy (the people that make sure all cars are road-worthy) Alvis added fuel-injection, disc-brakes, rounded off a few sharp edges, put a special mount under the bonnet mascot so that it breaks off in an accident, and fitted discreet indicators, fog lights and seatbelts.

Now called The Alvis Car Company, Alan and co-started building continuation cars in 2012, offering almost entirely faithful brand-new examples of the models it had been making pre-war.

But it’s since expanded its range of continuation cars to Alvis’ post-war 3.0-litre cars. Customers have got three bodystyles to choose from - Super Coupe, Cabriolet and Drop Head Coupe – all using aluminium panels and ash frames, mounted on an original steel chassis.

Customers have options. Lots of options. First off to choose whether to begin a build with a donor car (either one they already own or one supplied by Alvis from this shed) or to start from scratch.

Existing vehicles keep their original registration date; new builds are titled in the year they’re finished, so you’ll see a pre-war car with a 70-reg plate. That’ll pretzel the brain of a few pedestrians.

From there, there are plenty of options to choose from, including different body styles, paint colors, and upholstery types. Some models are recreations of prewar cars, like the Vanden Plas, while others are rooted in the 1960s, like the Graber.

Every car is hand-assembled from start to finish, a process that requires up to 5,000 hours of labour and can take up to two years.

Here’s the Aladdin’s cave of Alvis. There are 35,000 individual parts in here for a car – a quarter of a million in total. Quick fact: there’s one part that works across every model – a split pin that works in everything from a 1923 car to 1966.

This isn’t Amazon, though. There’s no automation. If they can’t find something, they just get the drawings out of the drawers and build them. Everything is exactly the same as back then.

You can see the bits that come together to build a car: brand new cylinder heads, blocks, camshafts, gear sets, pistons, cylinder heads, pumps, oil pumps, fuel pumps, water pumps, exhausts, lights, radiators… it’s a proper Lego set.

Costing £250,000, a continuation car from Alvis costs far less than others in the same genre. Admittedly, they don’t have the same cache as Bond’s DB5 but at least you know it’s true to the continuation name.

More importantly, Alvis is a brand that’s underrated and should be celebrated – part of Britain’s history and something with a proper story. So if you want a car from back in the day without the need for Bernard’s Watch, this is the place to come. Just tell them Top Gear brought you.