F1 supplier reveals off-the-shelf high-performance carbon road chassis for sale

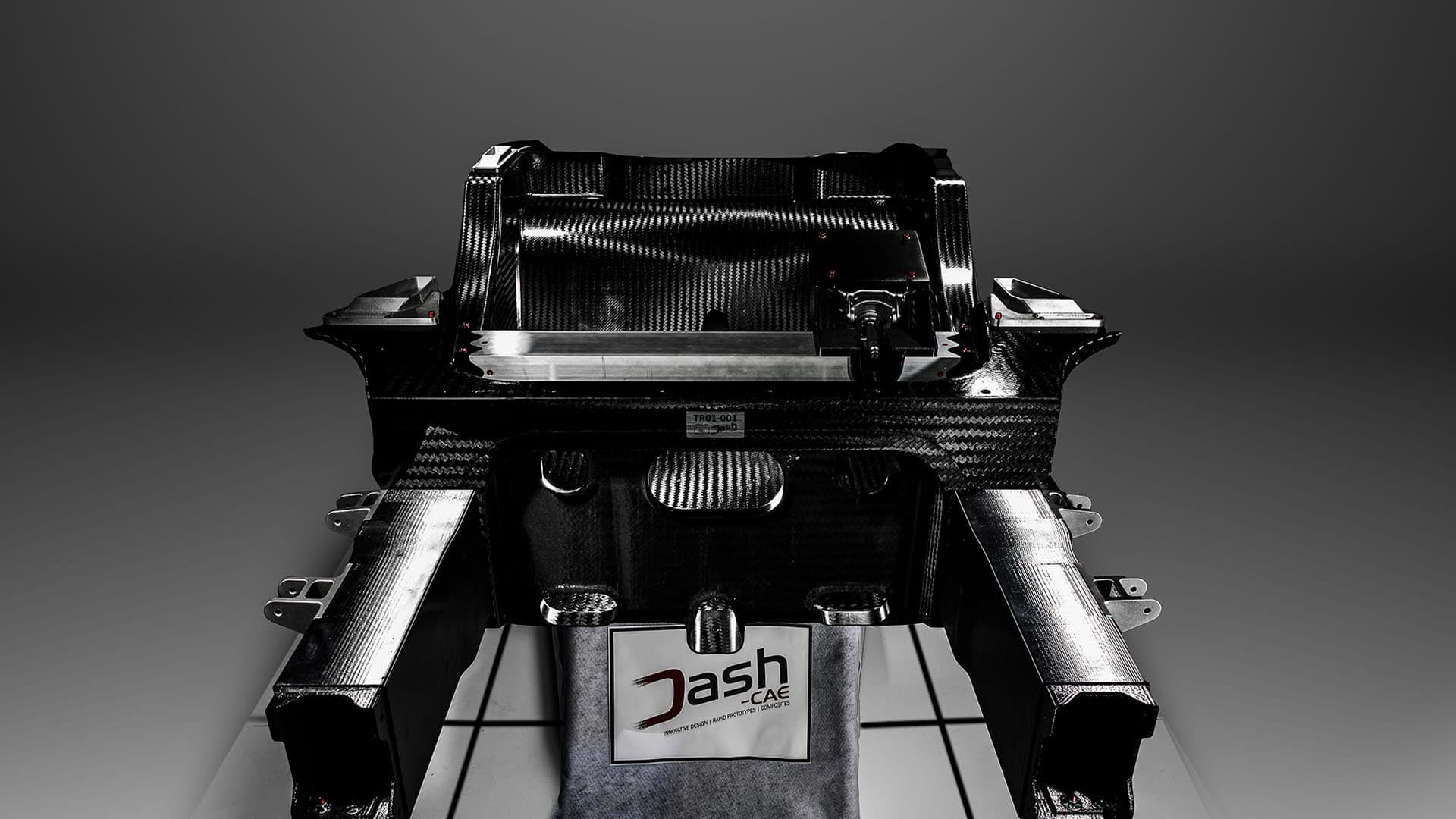

F1 supplier Dash-CAE reveals off-the-shelf high-performance carbon road chassis for sale

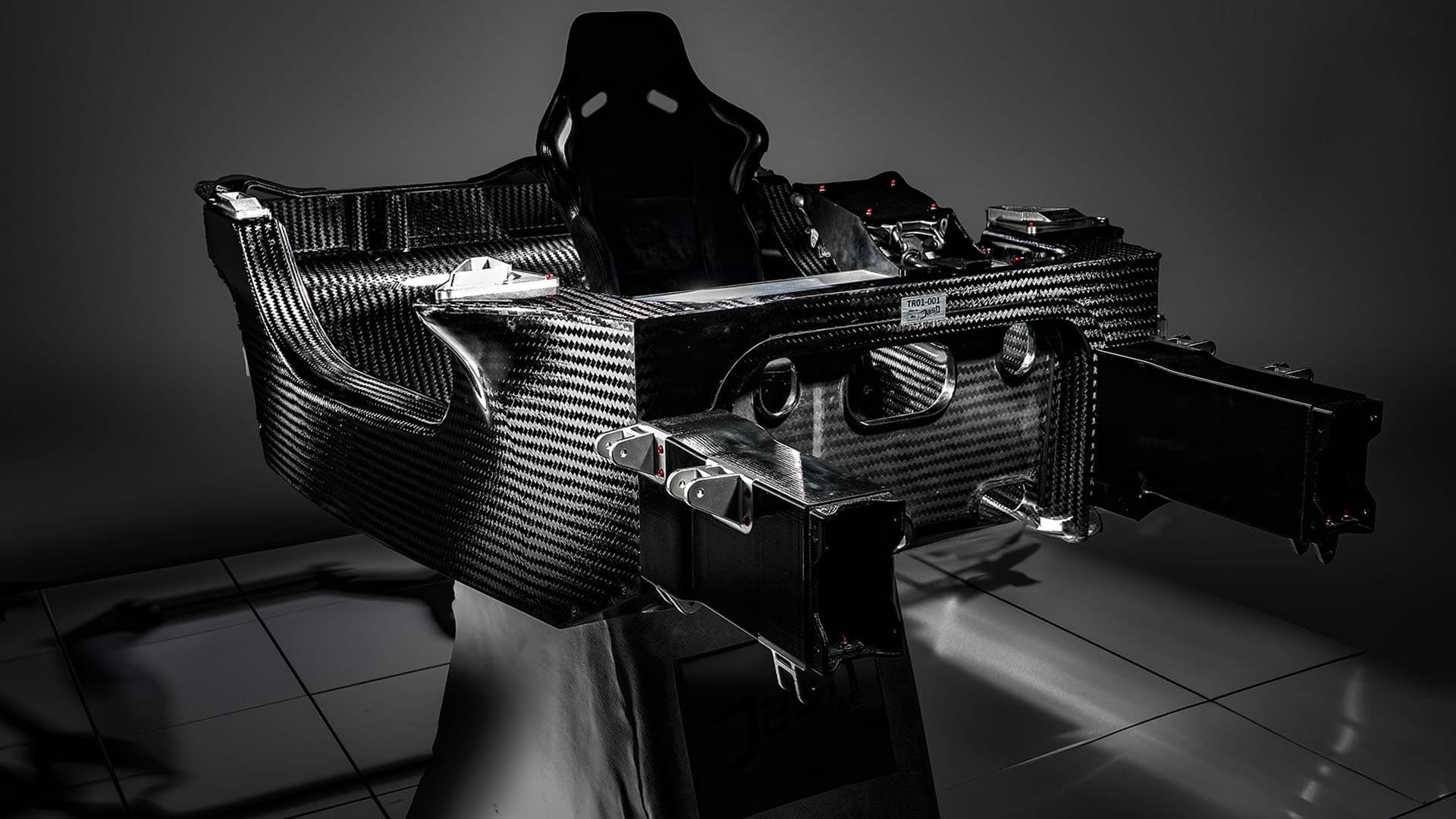

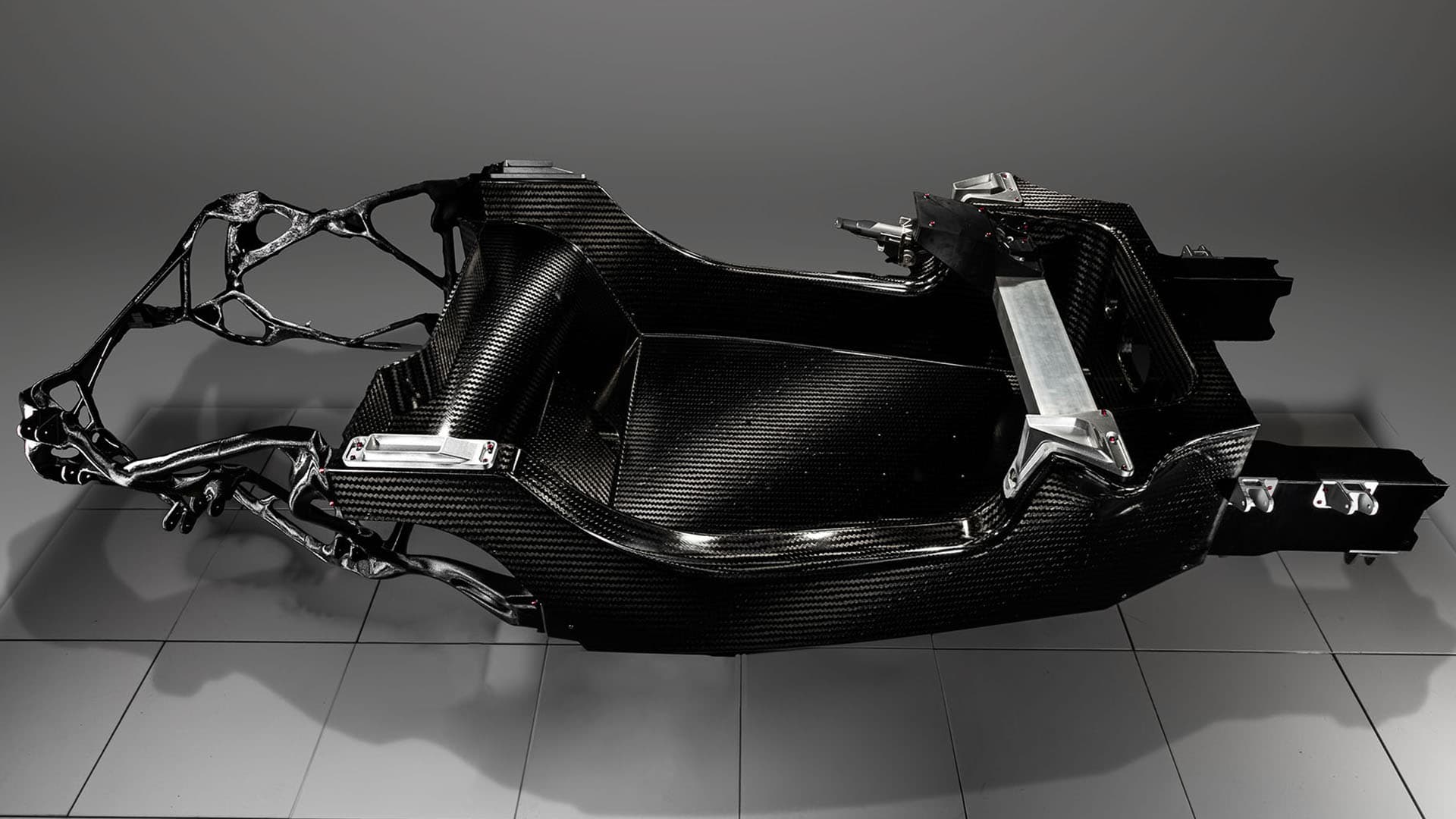

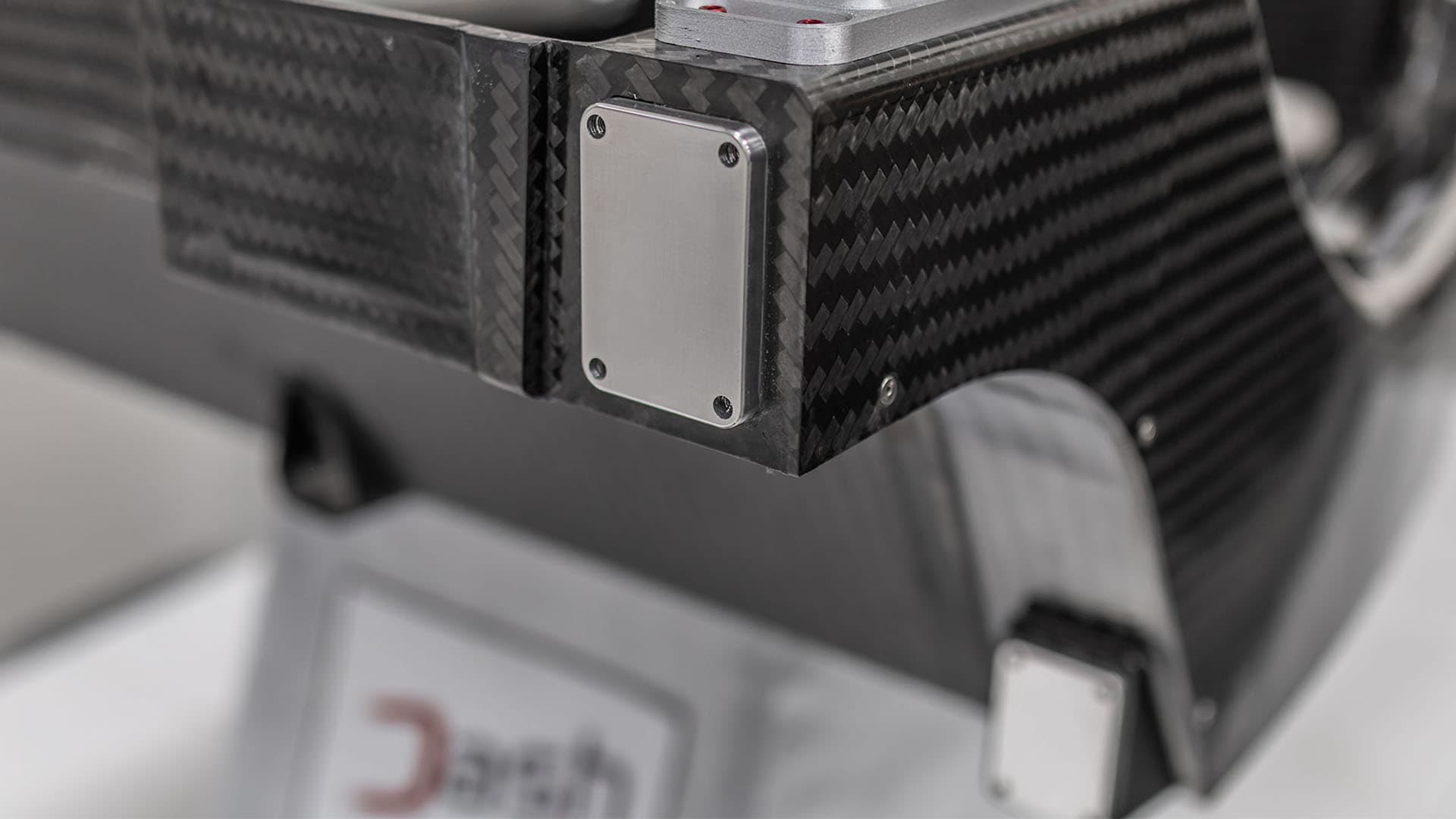

F1 supplier Dash-CAE has created a carbonfibre monocoque chassis for high-performance road cars. The TR01 is an off-the-shelf solution and is set to debut at the Goodwood Festival of Speed.

The specialist engineering firm has managed to spec out a monocoque chassis, suitable for a two-seater road car project, and promises it's three times stiffer and half the weight of steel.

What's more, the pricing for the TR01 starts at around £30,000 (about S$50k) per unit, depending on the volumes ordered.

While it might not offer exact parity with cheap steel, it's not, according to founder of Dash and ex-F1 engineer Tim Robathan, "stupid amounts more... and if you consider you don't need to make jigs, etc...", it's all sounding a lot more cost-effective.

Robathan told TG.com: “It had to be cost-effective, if it was gonna be available to anyone. [The spec meant] it had to be able to diversify into all kinds of vehicles, including ICE and electric powertrains.”

It’s kinda hard to fathom why, to date, there hasn’t been one of these available before. No surprises, it all comes down to money. By cutting the cost of obtaining this kit by almost 50 per cent, Dash's chassis solution not only opens the door for accessibility in hobbyist projects, but also saves time and cost for professional teams – whether in racing or road vehicle programmes.

“Countless people have, over the years, asked me for it. Recently, I was chatting with a European customer, working on a hypercar. They said ‘Ah, we’re probably going to go for cheaper steel, because the cost implications of a carbon chassis is too much for our budget.'”

Robathan advised they look at the Alfa 4C and made enquiries to track down a reliable supplier for this carbon monocoque chassis, which in Robathan's words was 'ahead of its time'.

Alas, after weeks of searching, no joy was to be had. Alfa itself wasn’t prepared to support the project (we're sure they had their reasons).

What is one man’s challenge, is another’s opportunity. Robathan and the team set about configuring and costing out a solution of their own, bringing their know-how about composite manufacturing to the fore.

Robathan is used to innovating. Back in the 1990s, he worked for Lotus while Senna was driving. His CV makes an interesting read and includes notable successes in rapid prototyping long before it was cool.

Since leaving F1 in 2013, Dash has broadened its portfolio to include Le Mans, GT and other sports cars. Although it's not a composite manufacturer, according to Robathan, Dash has world-leading composite facilities, oh and of course, a robot. (Though, not this kind of robot.)

While Robathan would be too modest to say he was one of those who pioneered 3D printing in F1, he acknowledged that Dash has built and programmed the UK’s first 3D-printing robots for large tooling in composite work – a feat that has taken six years to perfect.

"A lot of composite parts are hand trimmed and you can only trim to within a certain accuracy. The robots can just do it repeatedly, all the time. But they're quite hard to train. We've got that knowledge in-house now and I can see that the use of them in the composites industry is gonna become more and more significant."

STORY Cat Dow